| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Brand Name : DELONG TOOL

Model Number : WNMG080408 GS

Certification : CE、ISO9001

Place of Origin : CHINA

MOQ : 10pcs/package

Price : 1.5~3.5USD/PCS

Payment Terms : T/T

Supply Ability : 100000000PCS/Year

Delivery Time : 5day

Packaging Details : Plastic box(10pcs/package, white color), and cartons

Material : Tungsten Carbide

Customized : Non-Customized

Standard : DIN、GB、JIS

Application : Metal Processing Machinery Parts

Machining Method : Finish Semi-Finish Rough

Applicable materials : Steel parts stainless steel parts High temperature alloy

Shipment : TNT DHL EMS or by air

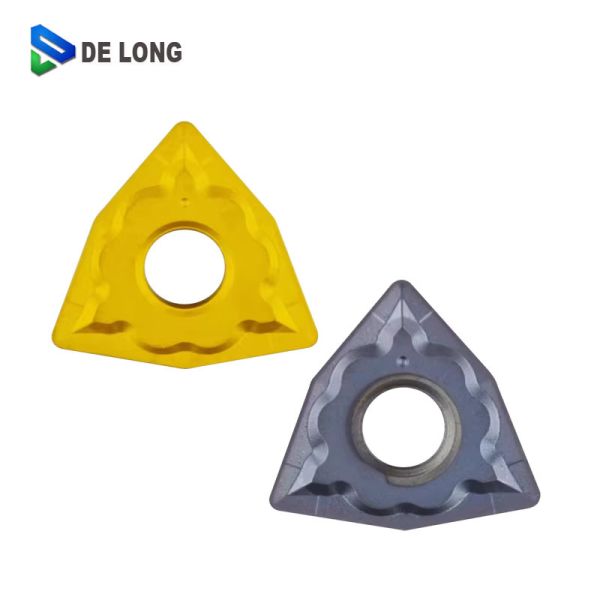

Negative Rake Angle WNMG080408 GS CVD Coating DLP101 and DLP102 For Steel Parts Machine

Brand: "DELONG" or OEM

Product description

We aim to OEM and cutomized order, we have the capacity of new design mold manufacturing for non standard carbide insert, cutting tools production. Please contact and leave your request to us, we will offer the best quotation to you.

Choose grades according to processing needs.

DLP101: Steel piece yellow P, CVD coating, processing steel parts below 28 °.

DLP102: Steel piece black P, CVD coating, processing steel parts within 45 °, modulated steel, and quenched steel.

Selling point:

1. High efficiency: Using imported substrates, PVD coating temperature is between 300-450, VCD coating temperature is between 800-950, and alloy substrate sintering temperature is between 1380-1460. The coating is thick and the blade is wear-resistant, which is more than four times more efficient than traditional alloy blade processing.

2. High wear resistance: prolongs service life, reduces replacement frequency, and lowers processing costs.

3. High precision: Ensure that the size and shape accuracy of the workpiece meet the requirements.

4. Durability: Maintain stable performance even under high loads and high temperatures.

5. Cost effectiveness: The initial cost may be high, but the long lifespan and high efficiency result in lower overall costs.

Feature:

Delivery time: 8-20 days, depends on the stock and productions.

Payment: 100% before shipment

unit weight: 9.5-28.7g/pc

Terms: Except for special explanation, all quotation are based on FCA Zhuzhou, Hunan, China, excluding freight and insurance

Packing: plastic box(10pcs/package, white color), and cartons

OEM: According to the requirement, supply neutral packing, without label and marking.

|

|

WNMG080408 DLP101 DLP102 Negative Rake Angle CNC Turning Inserts for Steel Parts Images |